- europages

- >

- ПРЕДПРИЯТИЯ - ПОСТАВЩИКИ ПРОДУКЦИИ - ПОСТАВЩИКИ УСЛУГ

- >

- system control

Результаты для

System control - Импорт экспорт

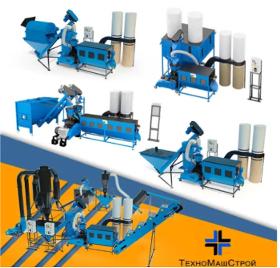

TECHNOMASHSTROY

Украина

Pelletizing lines of MLG series from the company "TechnoMashStroy" represent the equipment for production of pellets and mixed fodder. You can get acquainted with all existing variants of completions of installations for the production of pellets and mixed fodder, as well as you can buy separate units: granulator, hoppers with a uniform feed of raw materials, aerodynamic dryers for drying raw materials, humidification system, calibrator cooler of finished pellets, belt conveyors, closed exhaust system, control desk

Запросить смету

WISENT MACHINERY

Украина

The BOSA 6-150 FL carbonization furnace is a retort-type plant with frontal loading and unloading of removable retorts. The furnace has an automatic control system that controls the temperature in the furnace by controlling the corresponding flaps, the rotations of the exhaust funs and the emergency chimney cover. The furnace consists of six separate identical pyrolysis reactor housings. Each reactor body has its own "door", through which a retort with raw materials is installed in the reactor with the help of a forklift. To ensure the operation of the furnace on raw materials with a high percentage of moisture, the furnace is equipped with six pre-drying units. SPECIFICATIONS Overall dimensions — 18x18x6.3m The weight of the furnace — 68 tons Electricity consumption — 9.5 kWh Daily productivity on hardwoods — 6-6.5 tons of charcoal Monthly productivity on hardwoods - 180-200 tons of charcoal More detailed information on our website.

Запросить смету

OVOSTAR

Украина

Group of companies Ovostar Union is a TOP-5 egg producer in Europe. The poultry farms are equipped with up-to-date technologies. The production meets international industry standards for quality and food safety. Grading machines with three-stage detection system control the quality and cleanliness of the eggshell, additionally disinfect the eggs and precisely grade them by weight.

Запросить смету

UTF

Украина

Capacity: 100-250 kg/h Raw materials: flour Energy source for oven: electricity Control system is carried out with controller and TOUCHSCREEN Key features of the production line: - automatic washing of divider - option for add additional equipment automatic feeding of dough into bunker of extruder stacker for stacking for grouping products in a stacks - different recipe - design of lines can be developed according to customer production premises Equipment set of the line: - dough divider - press - feeding conveyor - two tired tunnel oven - cooling conveyor - inclined conveyor - two rowed stacker

Запросить сметуВы продавец или производитель подобной продукции?

Зарегистрируйтесь на europages и индексируйте свою продукцию

Результаты для

System control - Импорт экспортКоличество результатов

4 товарыTипу компании