- europages

- >

- ПРЕДПРИЯТИЯ - ПОСТАВЩИКИ ПРОДУКЦИИ - ПОСТАВЩИКИ УСЛУГ

- >

- equipment

Результаты для

Equipment - Импорт экспорт

SYNERGY-DREAM

Украина

This filling line is designed specifically for charcoal filling in craft-packets. The screener separates coal into four fractions: 0–3 mm fraction 3–12 mm or 3–20 mm fraction, depending on the installed sieve size (12 mm or 20 mm) 12–60mm or 20–60 mm fraction, depending on the installed sieve size (12 mm or 20 mm) 60+ mm fraction. Fraction No. 1 and No. 2 are discharged to containers to be transported by manual fork-lift for further processing. Fraction No. 3 is delivered to two watering pots for bag filling. Fraction No. 4 is delivered to other two watering pots for bag filling. A special device for separating coal flows by fractions can combine fractions No. 3 and 4 into the same flow; this means that all four watering pots can be operated with the same coal composition and th

Запросить смету

GRAIN ENERGY LLC

Украина

Productivity is 40 t / h, and energy consumption is 4.4 kW due to the use of a frequency converter of European production. The separator efficiency is very high. The grain entering the cleaning chamber from the hopper is influenced by the air flow, which divides the heap of grain according to the specific weight of the cleaned material and windage. Cleaned and calibrated material is delivered through 7 trays: - first of all, the largest debris falls (stones, land, stems, spikelets, etc.); - Material from the middle of a spikelet of wheat, corn cobs or sunflower caps is loaded into 2-3 trays. This is the most viable material of the whole heap, seed germination up to 98%; - the material from the lower part of the ear is placed in 4-5 trays - this is marketable grain, the variety that brings the greatest profit; - the grain on top of the spikelet (unripe, Light, semi-crushed grain), which significantly reduces the cost of the harvested crop falls into a 6-7 tray!

Запросить смету

GRAIN ENERGY LLC

Украина

DM feed mixer wagon. The DM is a forage mixer wagon that increases milk yield by utilising all forages evenly, which has been proven repeatedly by farms using this technology. It chops straw and hay and mixes it quickly with the other feed ingredients. Available in volumes from 2 to 16 m3 Benefits Significantly reduces labour costs Reduces feed waste by 30 Increases feed efficiency, resulting in 15% higher milk yields Robust galvanised fittings. Compactness Easy to operate Quick return on investment due to low maintenance costs Additional options Hydraulic bucket Positioning option: at the rear of the drum. Allows the mixer to be loaded independently (without the use of a loader) with different components. PTM weighing system (Italy) Allows you to programme 15 rations and prepare and distribute feed in the correct proportion.When used correctly, it significantly improves milk reliability and livestock growth. Additional damper

Запросить смету

GRAIN ENERGY LLC

Украина

The universal grain-cleaning separator of the BISS 40 model is designed for both primary cleaning (elevator mode) and final cleaning (mill mode) of a grain heap of cereals (wheat, rye, oats, etc.), cereals and legumes, industrial and oilseeds, grass seeds from light, large and small, weed and grain impurities, differing in geometric dimensions and aerodynamic properties, separated by an air flow and sieves, in order to bring the content of impurities in the harvested grain at elevators, mills, cereals, feed mills and other enterprises to a minimum values. NAME OF PARAMETER 1.* Technical productivity: preliminary cleaning - 40 t/h final cleaning (mill mode) for wheat - 12 t/h 2. Efficiency of cleaning from weeds,not less: - preliminary cleaning - 20 % - final cleaning (mill mode) for wheat - 80 % Possibilities to adjust the angles of inclination of the upper and lower sieves. It is possible to install aspiration columns, Cyclones.

Запросить смету

GRAIN ENERGY LLC

Украина

The ASM model separators can effectively clean the crop from debris and various impurities, and separate it into different fractions, depending on the size of the particles. Models are available in various capacities and specifications (from 5 to 50 t/h). The principle of operation: the grain (source material), falling under the influence of the air flow, depending on the weight, shape, surface roughness, floatation of each grain, has a different trajectory of flight. This makes it possible to clean both fine seeds or grains as well as coarse seeds (beans, beans, maize). Operates with maximum efficiency Grain is not injured by compressed air Minimal energy consumption Can be installed in confined spaces Easy maintenance Cleans material with high humidity Long lifetime due to modern manufacturing process

Запросить сметуВы продавец или производитель подобной продукции?

Зарегистрируйтесь на europages и индексируйте свою продукцию

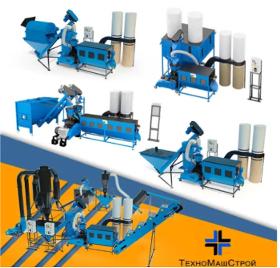

TECHNOMASHSTROY

Украина

Pelletizing lines of MLG series from the company "TechnoMashStroy" represent the equipment for production of pellets and mixed fodder. You can get acquainted with all existing variants of completions of installations for the production of pellets and mixed fodder, as well as you can buy separate units: granulator, hoppers with a uniform feed of raw materials, aerodynamic dryers for drying raw materials, humidification system, calibrator cooler of finished pellets, belt conveyors, closed exhaust system, control desk

Запросить смету

TECHNOMASHSTROY

Украина

The line for packing and packaging of pellets is a packaging complex that will simplify and automate production. You can purchase each unit separately or as part of the equipment for pellet production. We can provide you not only quality selection of equipment, but also help with installation, commissioning and training of your staff. You can contact the manager of our company by calling +38(097)006-48-43. You can contact the manager of our company by calling +38(097)006-48-43 (Viber/WhatsApp).

Запросить смету

UTF

Украина

Capacity: 100-250 kg/h Raw materials: flour Energy source for oven: electricity Control system is carried out with controller and TOUCHSCREEN Key features of the production line: - automatic washing of divider - option for add additional equipment automatic feeding of dough into bunker of extruder stacker for stacking for grouping products in a stacks - different recipe - design of lines can be developed according to customer production premises Equipment set of the line: - dough divider - press - feeding conveyor - two tired tunnel oven - cooling conveyor - inclined conveyor - two rowed stacker

Запросить смету

RATIONAL TECHNOLOGIES OF BUILDING

Украина

Преимущества производства пенобетона на оборудовании " К.С.У." по технологии «Фомрок»: •Рентабельность – себестоимость материала получаемого на оборудовании " К.С.У." ниже по сравнению с другими типами оборудования. •Производительность – мобильно-стационарные комплексы " К.С.У." позволяют изготавливать от 3 до 30 м3 пенобетона в час НЕПРЕРЫВНО. •Малый вес - общая масса оборудования и оснастки мини-заводов 380-900 кг. Самая тяжелая часть установки весит около 120 (400) кг и находится на колесах. Главное устройство – пневмодинамическая система смешивания со встроенным пеногенератором - весит всего 10 кг! •Мобильность - мобильный комплекс " К.С.У." легко перемещается на колесах, что позволяет изготавливать и укладывать монолитный пенобетон необходимой плотности в любом месте и на любой высоте, что невозможно при использовании другого оборудования. Для доставки мини-завода к месту производства работ нужен один рейс небольшого грузового автомобиля.

KOLESNIK

Украина

Reel Lifting Trolley RLM designed for moving and lifting, loading and unloading rolls up to 500 kg. The winch with a manual drive makes the Roll Lifter simple and easy to operate, an indispensable assistant in warehouses, storage facilities, shops, and enterprises. The use of a hand winch as a lifting mechanism ensures smooth and uniform movement of the lifting carriage.

Запросить сметуРезультаты для

Equipment - Импорт экспортКоличество результатов

11 товарыTипу компании

Kатегории (рубрике)

- Сельскохозяйственная и лесохозяйственная техника и оборудование (2)

- Восстанавливаемые энергоресурсы (1)

- Добыча руды (1)

- Ленточные конвейеры (1)

- Оборудование для кормления скота (1)

- Пищевая промышленность - машины и оборудование (1)

- Строительство - машины и материалы (1)

- Упаковка в мешки и пакеты - машины и оборудование (1)

- Фасовка и упаковка (1)

- Штабелёры (1)

- Элеваторы сельскохозяйственные (1)